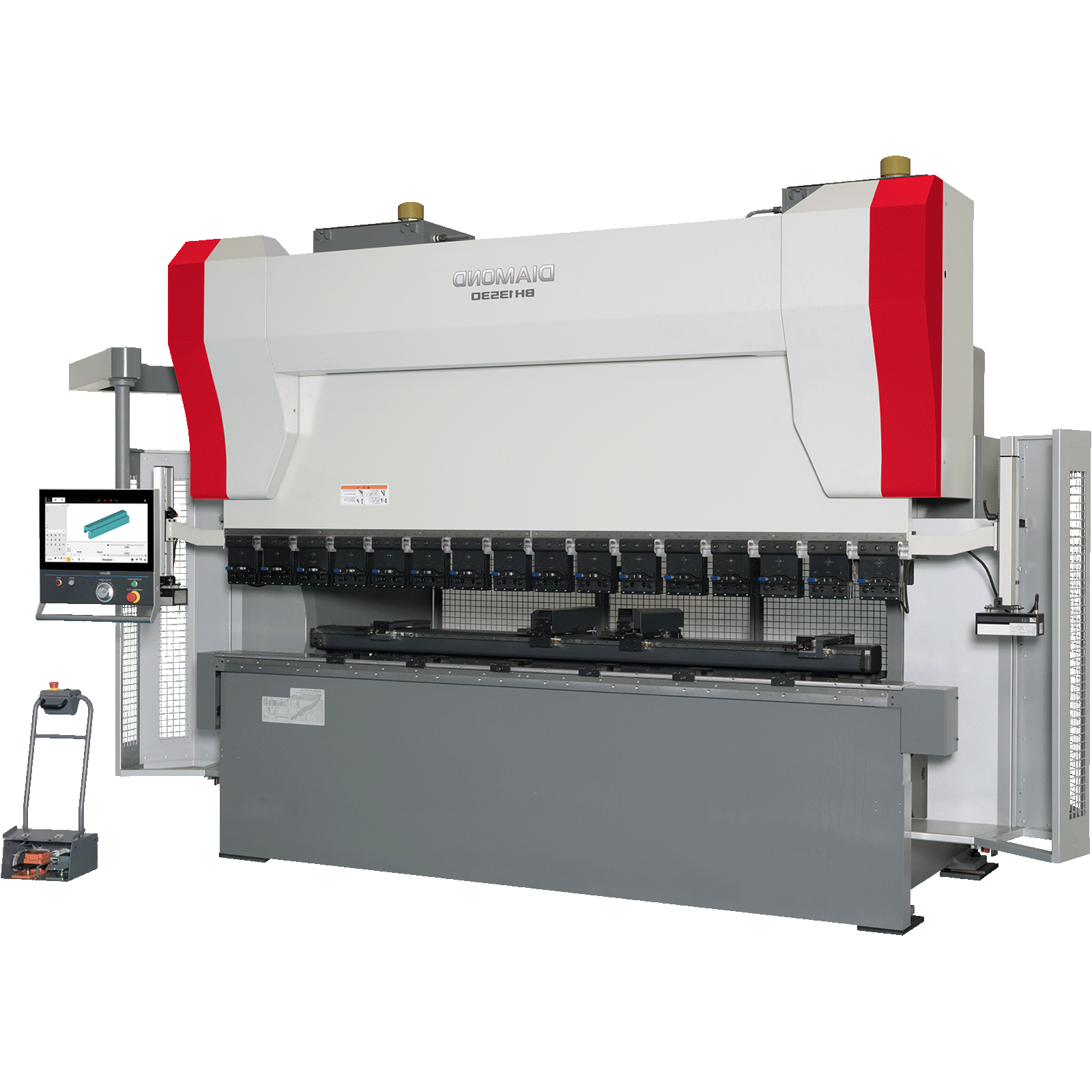

The PA Plus series combines functionality and versatility in one powerful package. The PA Plus series is designed for a large array of accessories for a customizable solution.

When you hear “hydraulic press brake,” you might immediately think of raw, powerful bending on even the longest or thickest pieces. And that’s certainly true. But what if you could apply that kind of performance in any situation—regardless of project requirements, piece dimensions, or other variables?

That’s the true benefit of the PA Plus series’ extreme customizability: You’re getting the performance of a hydraulic press brake, plus the confidence that comes with knowing your bending department will always be ready for anything.

PA Plus Series

- With the ability to modify and configure your machine with different options and accessories, you can turn a PA Plus series press brake into many different machines at once. Best of all? What you decide to do with the money you’ll save by needing fewer different machines, resources, and labor is all up to you.

MAXIMUM RESULTS, MINIMUM EFFORT

- An easy, intuitive 15” color multi-touchscreen makes day-to-day operations quick and efficient by empowering your operators to do their best work—and achieve peak performance—under nearly any circumstance with minimal training or oversight.

STABILITY YOU CAN COUNT ON

- Designed with a HEXA-C® frame that ensures a perfect guiding on the upper beam even when under load when compared to a standard C frame/O frame, the PA Basic series press brakes are built to perform. But solid construction isn’t the only reason to rely on this machine. It’s backed up by our department of technical experts, making it easy to get the know-how you need whenever you need it.

CAPABILITIES:

- The PA Plus series is our most customizable hydraulic press brake, allowing you to build the perfect machine for any situation you come across or modify it to meet the needs of tomorrow.

- Ensures a perfect guiding on the upper beam even when under load when compared to a standard C frame/O frame thanks to its revolutionary, highly stable HEXA-C® frame design.

- It gives you the flexibility to tackle a wide range of jobs with diverse material requirements thanks to its high open height, stroke, and throat depth.

- It allows you to prioritize worker safety with its integrated LazerSafe safety system.

- Delivers fast, accurate work with ease due to its powerful multi-axis back gauge.

- Achieves extraordinary energy savings with its motor “Start/Stop” system that switches off if the machine stays idle for a set time.

- It comes with a host of standard components that work together to ensure quality work day after day, such as effective hydraulics with overload protection, Wila crowning, oil cooler, sheet supports, and more.

USER INTERFACE:

- 15” CNC touchscreen with additional alphanumeric support keyboard

| MODEL | PA Plus – 13530 | PA Plus – 13540 | PA Plus – 16030 | PA Plus – 16040 | PA Plus – 22030 | PA Plus – 22040 |

| Press Force: metric (US) | 135 (149) | 135 (149) | 160 (176) | 160 (176) | 220 (242) | 220 (242) |

| Bending Length: mm (in) | 3,000 (118) | 4,000 (157) | 3,000 (118) | 4,000 (157) | 3,000 (118) | 4,000 (157) |

| Back Gauge Axis | 4/5/6 | |||||

| Open Height: mm (in) | 500 (20) | |||||

| Ram Stroke: mm (in) | 260 (10) | |||||

| Gap Depth: mm (in) | 400 (16) | |||||

| Distance Between Frames: mm (in) | 2,550 (100.4) | 3,150 (124) | 2,550 (100.4) | 3,150 (124) | 2,550 (100.4) | 3,150 (124) |

| Strokes/Hour (SPH) | 960 | 960 | 960 | 960 | 900 | 900 |

RELATED SOLUTIONS

-

ELECTRIC PRESS BRAKES

Mitsubishi electric press brakes are known for speed, efficiency, and reliability.

learn more -

HYBRID PRESS BRAKES

This Mitsubishi dual-drive hybrid press brake makes short work of any project with its high speed, energy-efficient operation.

learn more -

HYDRAULIC PRESS BRAKES

High productivity, heavy-duty bending performance, and intuitive operation in a cost-efficient package.

learn more -

PRESS BRAKE AUTOMATION

Real-time information from this game-changing Mitsubishi tool changer lets any press brake operator perform at their best.

learn more

-

"The accuracy and repeatability are outstanding. I had one job running for five days straight—there was no difference from the first part bent on day one to the last part bent on day five. All of this plus the reduced setup time translates into higher profitability."

Milan Popik Jr, Owner at Metal Tronics view case study -

"“Press brake operators of all skill levels can easily set up complex jobs. This saves tremendous time and resources. Press brakes have not changed that much mechanically over the years, but technology like automation and diagnostics can really set you apart from the competition."

Eugenio Martin, Lynam Inc. manufacturing engineering manager